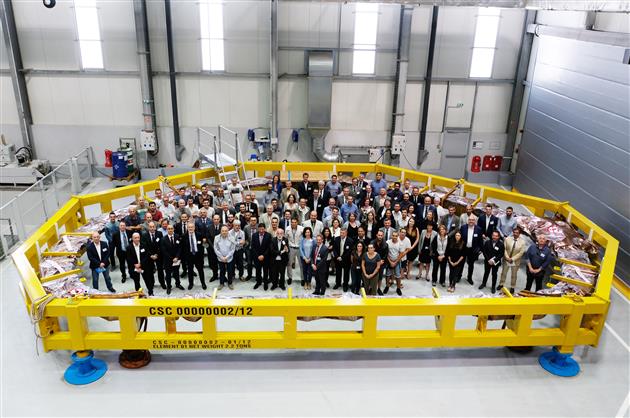

Europe’s final radial plate, which will house in its finely machined grooves the superconducting conductor of the ITER Toroidal Field coils (TF), has been manufactured. The contract signed between F4E and the consortium between SIMIC and CNIM, has been successfully concluded.

On Tuesday 23 May, the impressive D-shape component measuring 13 x 9 m and weighing roughly 10 T, sailed from the port of La Seyne-Sur-Mer (France) to La Spezia (Italy) to join the production line of Europe’s TF coils in the facility of ASG Superconductors.

The production of all 70 radial plates has been completed in line with the tight schedule and budget. The collaboration of the two companies, which are different in size and are operating in two different countries, is in itself a European success story. We have shared the workload, our know-how and have worked hand in hand to meet the requirements of this demanding task. This partnership is also congruent with the spirit of international collaboration that the ITER project promotes.

Over the last four and a half years in the facilities of SIMIC and CNIM, that were upgraded with new tooling and new people, the high-tech machines have been working relentlessly under the supervision of dedicated teams rotating three times per day. After having completed the inspection of the last radial plate, the component has been carefully packed, loaded on MV STAPELMOOR, the vessel which will cross the sea one more time to deliver it safely to La Spezia.

The material used, the quality of welding, the scale of the parts, the dimensional tolerances and the pace of manufacturing have made this a very complex project, both in terms of technology and project management. SIMIC has adapted its range of industrial tooling and acquired a giant portal machine (18 x 10 m), PAMA brand, housed in a air-conditioned facility with direct access to the sea, which is vital for the transportation of the radial plates to final destination.

The processes implemented for the production of the radial plates – Narrow gap Tig automatic welding and final machining – were developed under a contract with F4E between 2009 and September 2012. This made it possible to achieve exceptional levels of performance in terms of tolerances and welding quality.

The fabrication of the radial plates has been counting more than 300 000 hours of work for SIMIC. “Thanks to the hard work and competence of the teams, SIMIC has managed to meet the project objectives, respecting the tight delivery schedule of one radial plate every three weeks”, explains Marianna Ginola, SIMIC responsible for the ITER program. “It has been 4 years of intense work, a long journey made of hard challenges and continuous learning and improvement.”

Eva Boter, F4E's Technical Officer managing this contract, recalls how it all started: "We needed to develop a series of smaller prototypes in order to reach the full scale components. It was an exercise in many stages. With every step we made we gained confidence. I remember when we presented at MT-22, the Magnets Technology conference, parts of the real size mock-ups of the radial plates, and people were gathering to view them. They were fascinated by the machining and precision that underpin this equipment.”

Alessandro Bonito-Oliva, F4E’s Project Manager for Magnets, remembers the first information meeting that took place almost eight years ago where companies expressing interest in the fabrication of the radial plates were invited to F4E. “We have come a long way since that meeting where we needed to figure out who was interested in their production, understand if they had the know-how and whether they would they be inclined to compete. Today, we stand in front of the final radial plate ready to find its way to ITER. I would like to congratulate our industrial partners for this achievement and the members of the team. Europe has proudly concluded one of its main contracts in the area of magnets.”

Italiano

Italiano English

English русский

русский